NEWS

|

Smallest and lightest in the world GX-3R The newly developed dual-sensor configuration reduces size by approximately 30% compared to previous models. Light weight (about 100g) means it won’t interfere with your work. GX-3R Pro Up to 5 gases can be detected with one device: It detects O2, H2S, CO2 and CO, in addition to SO2 and various other toxic and combustible gases. Intrinsically safe explosion-proof construction and flame-proof enclosures Water and dust resistant, IP66/68 Robust design (Withstands 7m drop).

|

|

This gas detector is designed to assure safety The GX-Force 4-Gas (O2, LEL, H2S, CO) Monitor assures worker safety through reliable R-Sensor technology with 3-years warranty, and a rugged, compact & light-weight body, as well as 30 hours of battery life. |

|

All in one explosion-proof gas calorimeter which features high accuracy, continuous measurement and high-speed response. Measurement data can be updated every 0.25 seconds, a feature which is not possible with gas chromatography. Robust design for all measurement environments eliminates the risk of measurement outages. |

|

RTGMS makes a difference RTGMS is a semi-custom made system that combines Riken Keiki's proprietary gas detection and alarm units with calorimeters. By combining our existing gas detection and alarm units with calorimeters,we have managed to produce gas monitors that meet the requirements of customers.

|

|

RIKEN KEIKI's portable gas monitors have been certified to the MED regulations. Riken Keiki is one of the only gas detection manufacturers whose range of marine instruments are certified to the MED regulation. Are you still using gas detectors at the end of their service life? It is mandatory for EU flagged vessels to comply with the MED Directive, and member states have an obligation to undertake market surveillance to ensure compliance.

Products certified as meeting requirements of Marine Equipment Directive 2014/90/EU will be accepted by all European and most non-European flag states. |

|

Are you still using gas detectors at the end of their service life? Gas detectors are vital equipment that can have life or death consequences. Use them properly to protect crew members from accidents. Gas detectors and other precision equipment generally have a service life of 10 years in a clean environment. It is recommended that gas detectors be inspected, repaired and replaced by manufacturers during the ship inspection twice every five years.** |

|

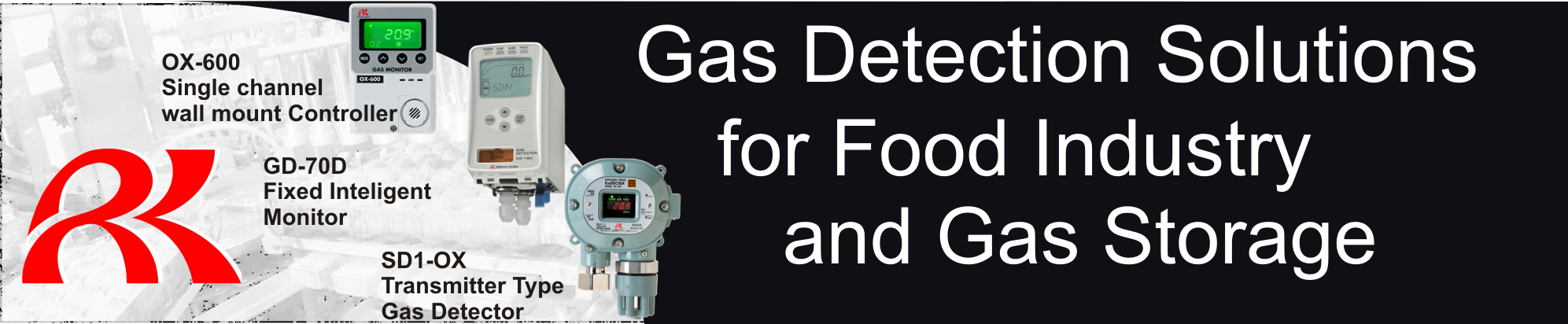

Riken product advantages for Lithium-ion Battery Production Riken Keiki has developed gas detection solutions for all production processes of lithium-ion battery manufacturing, which are typically high temperature environments. By utilizing direct insertion and heat resistant gas detection technology, accurate gas monitoring can be achieved in high temperature conditions often required by coating and drying processes. |

|

Combining high-precision Riken gas sensor technology to support decarbonization RIKEN KEIKI’s patented technologies are integrated into a number of its gas sensors, and by combining these sensors together, it is possible to measure gas in a variety of situations. |

|

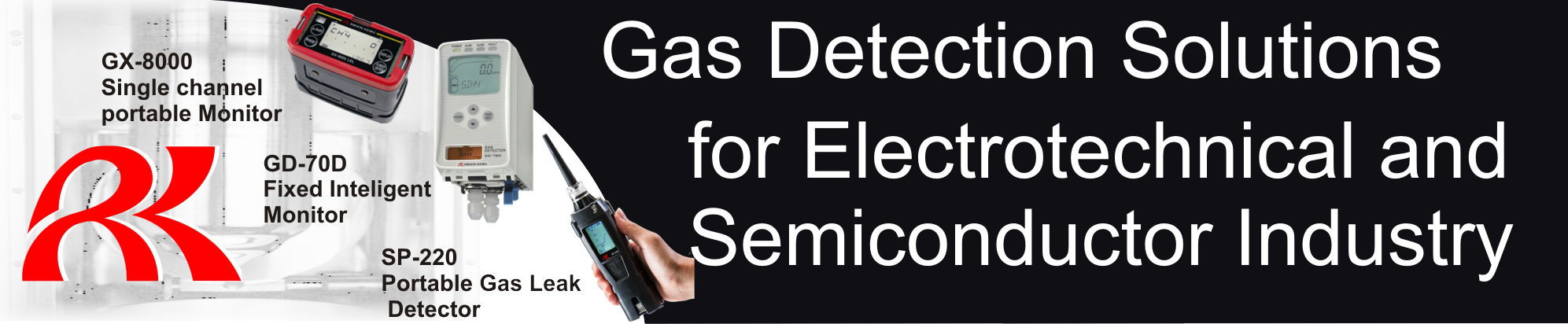

Extensive Range of Detection Gas Types and Riken Sensors With the growth of the semiconductor market, RIKEN KEIKI has developed over 600 types of gas sensors covering new and desired target gases (principle × gas × concentration). The long-selling GD-70D has a lineup of more than 260 types, supporting detection of a variety of gases. Custom-ordered sensor development and sensitivity surveys are also possible. |

|

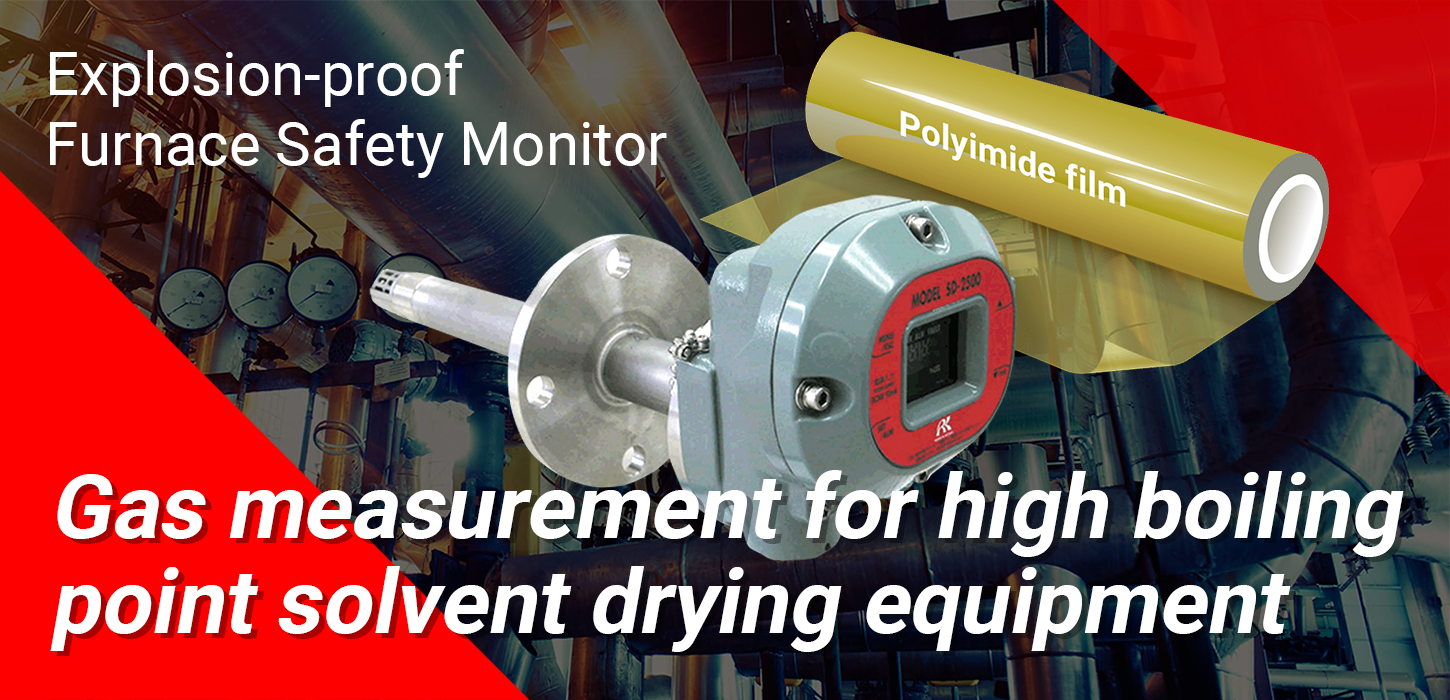

Riken product advantages for high boiling point solvent drying equipment Explosion-proof, direct-insertion type sensor, can withstand temperatures of up to 200°C Furnace direct-insertion type sensor, accurately catches concentrations in the central part of the exhaust duct. Enables detection of true values inside furnaces which cannot be measured by sampling, such as for high boiling-point solvents. |

Tradeshows

|

A+A 2023Under the slogan "Impulses for a better working world", the world's largest exhibition for safety and health at work took place in Düsseldorf this year. We would like to thank everyone who visited our booth from 24 to 27 October and took the opportunity to find out more about our innovative products. It was a pleasure to be able to engage in conversations with experts and interested people from the industry and talk about how we can further promote safety in the workplace. Even though the exhibition is over, our mission continues. We look forward to continuing to work with you in the future to make the working environment safer. |

SEMICON Europa 2023A big thank you to everyone who visited us at our stand from 14 to 17 November. It was a pleasure to present our innovative technology for the future of gas detection. We look forward to seeing you again at the next trade fair! |